Hakanan ana kiran fasahar buimond waya azaman fasahar cinye fasahar cutar. Amfani da hanyar da ba za a iya amfani da ita ba ko guduro ta hanyar haɗin kai na lu'u-lu'u daga saman karfe, waya mai sihiri kai tsaye a saman sanyama, don cimma sakamakon yankan. Yankan waya mai launin lu'u-lu'u yana da sifofin saurin yankuna da sauri, babban yankan yankewa da rashi karancin abu.

A halin yanzu, kasuwar kristal guda ɗaya don ci gaba da silond na yankan silond na yankan silond na haɓaka, amma ya ci gaba da ci gaba da haɓaka, a ciki wanda ya fi karama matsala shine matsalar gama gari. Ganin wannan, wannan takarda tana mai da hankali kan yadda za a hana bushe bushe na monocrystalline silik.

Tsarin tsabtace lu'u-lu'u na yankan kayan silnond na monocranstalline silicon zai cire silikon kayan aiki daga farantin mashin, ka cire tsararren roba, kuma tsaftace silicon wafer. Kayan tsabtace tsaftacewa shine mafi yawan mashin tsabtatawa (inji dalizanci) da injin tsabtatawa. Babban tsabtataccen tsari na na'ura mai tsaftacewa shine: ciyar-shakkar-ciyarwa-ultrasonic tsabtatawa-defe-mai tsabta ruwa-tsabta ruwa rinsing-shinke. Babban tsabtatawa ne na injin tsabtatawa shine: ciyar-ciyarwa mai tsabta mai wanka da alkyatse-alkalis (jinkirin da aka girka.

Ka'idar Velvet Velvet mai-Crystvet

Monocrystalline silicon wafer shine halayyar lalata cututtukan ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwaƙwalwar ta. Tsarin martani na dauki ne nazarin da aka yi wa sinadarai masu zuwa:

SI + 2SHOOH + H2O = Na2sio3 + 2h2 ↑

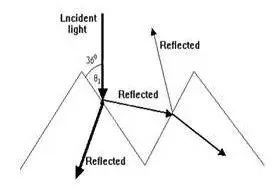

Ainihin, tsari na fata shine: na bayani don yawan lalata crosstal daban, (111), don haka (111), don lalata silisline daban, ƙarshe) an kafa shi a farfajiya don (111) A cikin mazugi mai gefe huɗu, wato "tsarin" tsari (kamar yadda aka nuna a hoto 1). Bayan an samar da tsari, lokacin da hasken ya faru ne ga gangaren dala a wani kusurwa, samar da sakandare ko fiye da haka a farfajiya na silicon wafer wafer , wannan shine, sakamako mai haske (duba Hoto na 2). Mafi girman girman da daidaituwa na "dala", mafi bayyana a bayyane yake tarko, da kuma kasan saman fitar da wafer wafer wafer.

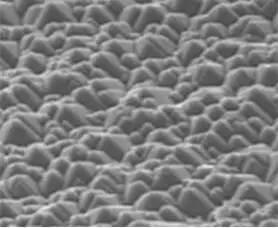

Hoto 1: Micrromorphology na Monolrystalline Silicon Wafer bayan Alkali Production

Hoto na 2: Haske Trap manufa na "Pyramid"

Nazarin guda ɗaya na crystal

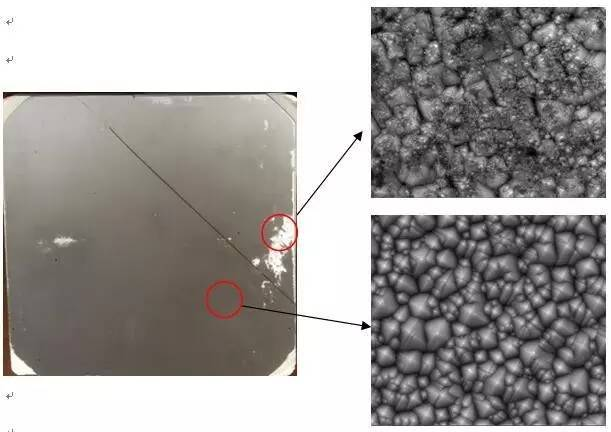

Ta hanyar bincika micraf wafer wafer, an gano cewa Pyramid Microstruchecture na farin White Ba a cikin yankin "Walker" Roudee, kuma Raba da alama yana da ragowar "Walamid" na fata A cikin farin yanki na wannan silicon wafer an kafa shi mafi kyau (duba Hoto 3). Idan akwai nutsuwa a saman monocrystalline silicon wafer, farfajiya zai sami yanki mai kyau "pyramid" tsari da kuma tasirin yanki da kuma tasirin yanki da kuma tasirin yanki na yau da kullun ya fi yankin al'ada, da Yankin da tare da babban magana idan aka kwatanta da yankin al'ada a cikin gani ya nuna fari. Kamar yadda za a iya gani daga yanayin rarraba fannon, ba tsari na yau da kullun bane ko kuma na yau da kullun a cikin babban yanki, amma a yankuna na gida ne kawai. Ya kamata ya kasance cewa masu gurasar na gida a saman silicon wafer wafer ne ya haifar da gurbataccen gurbata.

Hoto na 3: kwatanta bambanen microstructure na yanki a cikin farin farin silicon wafers

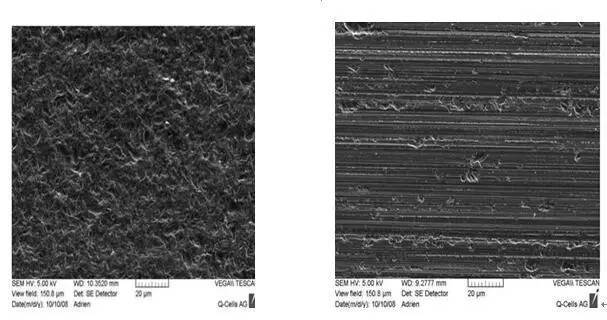

A farfajiya na lu'u-lu'u waya yankan silikon wafer yafi santsi kuma lalacewar ita ce karami (kamar yadda aka nuna a hoto na 4). Idan aka kwatanta da silicon mai wafiyõka, saurin amsawar alkali da lu'u-lu'u a farfajiya na monocronstalline silikanci, don haka tasirin sharan gona da iri mai kyau.

Hoto 4: (a) Motar kwari na turmi yanke silicon wafer (b) Motar launi na lu'u-lu'u waya yanke silicon wafer

Babban tushen yanayin lu'u-lu'u waya-yanke silikon wafer surface

(1) sanyaya: babban abubuwan haɗin lu'u-lu'u waya na sanyaya kayan maye, watsawa, lalata maras ruwa da ruwa da sauran abubuwan haɗin. A yankakken ruwa tare da kyakkyawan aiki yana da madaidaiciyar dakatarwa, watsawa da ikon tsarkakewa. Surfacts yawanci suna da ingantattun kaddarorin Hydrophilic, wanda yake da sauki a tsabtace a cikin silicon mai tsabtace tsabtatawa. A ci gaba da motsa jiki da kuma kewaya waɗannan abubuwan da ke cikin ruwa zai samar da babban adadin coolant, wanda ya haifar da matsalar kumfa, wanda zai iya shafar amfani da shi. Sabili da haka, ana amfani da coolant da yawanci tare da wakilin defoaming. Domin tabbatar da defoaming wasan kwaikwayon, silicone na gargajiya da polyether yawanci m hydrophilic. Maƙƙarfan ruwa yana da sauƙin zuwa Adsorb kuma ku kasance a saman wafer wafer wafer a cikin tsabtatawa masu zuwa, wanda ya haifar da matsalar farin tabo. Kuma bai dace da manyan abubuwan haɗin da sanyaya ba, sabili da haka, dole ne a ƙara ainihin abubuwan da aka yi, a tsakani, a cewar yanayin kumfa, ba zai iya sarrafa mai yawa ba amfani da kuma sashi na wakilai na Anoftoam, na iya ba da damar yawan kwararar ruwa na wakilan silikon, har ma da karancin farashin kayan masarufi da kuma defoaming wakili baw Kayan aiki, sabili da haka, yawancin abubuwan tarihin cikin gida duk suna amfani da wannan tsarin dabara; Wani mai sanyaya yana amfani da sabon wakilin defoaming, na iya zama mai dacewa tare da adadin abubuwan da suka haɗa, da yadda ya kamata ya magance yawan amfani, tare da tsarin tsabtatawa ya dace. Za'a iya sarrafa sharan a kan ƙananan matakan, a Japan da fewan masana'antun na gida suna ɗaukar wannan tsarin kayan aikinta, fa'idar farashin ta ba a fili ba.

(2) Manne da guduro version: A cikin wani mataki na yankan yankan yankan kayan lu'u-lu'u na lu'u-lu'u, da aka yanke wa ƙarshen silicon a ƙarshen sillet din ba tukuna a yanka, farkon yanke lu'u-lu'u Wire ya fara yanke wa faranti da kuma sake gina farantin, tunda silicon sanda na silining na asali ne tsakanin 55 da 95 ℃, idan taushi ta hanyar roba ko guduro Farantin yana da ƙasa, yana iya saurin zafi a lokacin yankan tsari kuma haifar da shi ya zama mai laushi da narkewar ƙarfe da kuma silond ɗin layin lu'u-lu'u kuma Cika da guduro tare, da zarar an haɗe, yana da matukar wahala a wanke, irin wannan gurbataccen yakan faru kusa da gefen wafer wafer wafer.

(3) silicon foda: A cikin aiwatar da lu'u-lu'u waya zai haifar da mai yawa silicon foda, tare da yankan, lokacin da foda ya fi girma ,, lokacin da foda ya isa, Kuma yankan waya mai lu'u-lu'u na silicon girman silicon da girman kai kai ga adsorption a kan silicon a farfajiya, yana da wahala tsafta. Saboda haka, tabbatar da sabuntawa da ingancin sanyaya da rage foda a cikin sanyaya.

(4) Wakilin Tsabtarwa: Amfani da amfani da na yanzu na yankan yankan yankakken a lokaci guda, mafi yawa suna amfani da fasahar yankan fasahar. Kammalallen layin layi, mai sanyaya da kuma ciyawa da kuma tsari mai girma, tsari mai dacewa, tsabtace wakili, da sauransu ya kamata don yankan kayan waya yana yin daidaitawa. Wakilin Tsaftace bangare ne mai mahimmanci, ainihin tsabtatawa ba ta dace da tsaftacewa da Silond Waficon ba, da kuma tsayayyen jeri na wakilin tsabtace na tsaftacewa, kuma ɗauka tare da tsarin tsabtatawa. Kamar yadda aka ambata a sama, abun da ake ciki ba a buƙatar wakilin defoaming a cikin yankan turmi.

(5) Ruwa: Yankan launi ta Diamond, pre-wanka da tsaftace ruwa ya mamaye m, ana iya tallata wa saman wafer wafer wafer.

Rage matsalar yin gashin gashi farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin farin fari

(1) Don amfani da sanyaya tare da kyakkyawar watsawa, kuma ana buƙatar sanyaya mai kyau don rage ragowar abubuwan da ke cikin sanyaya a saman wafer wafer;

(2) Yi amfani da manne da ya dace da resin plate don rage gurbataccen wafer wafer;

(3) An dilatar da sanyaya da tsarkakakken ruwa don tabbatar da cewa babu mai sauƙin shayarwa a cikin ruwan da ake amfani;

(4) domin saman lu'u-lu'u waya yanke silicon wafer, yi amfani da aiki da tsaftace sakamako mafi dacewa da tsabtatawa tsabtatawa;

(5) Yi amfani da layi na dawo da lu'u-lu'u na dawo da lu'u-lu'u don rage abun cikin siliki a cikin tsarin yankan, don magance ragowar siliki sosai a farfajiyar wafer. A lokaci guda, shi ma zai iya ƙara haɓaka zafin jiki na ruwa, yana gudana da lokaci a cikin pre-wanka, don tabbatar da cewa silicon foda yana wanka a cikin lokaci

(6) Da zarar silikon an sanya siliki a kan tebur tsabtatawa, dole ne a bi da shi nan da nan, kuma kiyaye silikon wafer rigar yayin tsabtatawa.

(7) Wafer wafer na da silikon yana riƙe da rigar rigar a cikin tsari, kuma ba zai iya bushe da sauƙi ba. (8) A cikin tsabtatawa na Silicon Wafik Walaf, lokacin da aka fallasa a cikin iska za a iya raguwa har zuwa dama don hana samar da fure a saman wafer wafer wafer.

(9) Ma'aikatan tsaftacewa ba za su tuntuɓar saman wafer wafer wafer a lokacin tsabtatawa na tsabtace ba, don kada su fitar da safofin hannu na roba, don kada su fito da buga rubutun yatsa.

(10) A cikin tunani [2], ƙarshen baturin yana amfani da tsarin H2O2 + Alkali Nah bayani gwargwadon ƙarfin girma na 1:26 (3% nah bayani), wanda zai iya rage abin da ya faru na matsalar. Ka'idar sa yayi kama da mafita na tsabtace SC1 (wanda aka fi sani da ruwa 1) na siliconctors silicon wafer wafer. Babban kayan aikinsa: fim ɗin iskar shaye-shaye akan silinon waferilon an kafa ta hanyar hadawan cikin H2O2, wanda ya wuce hadin-shawa da Nawakan da Nakasassu, wanda ya wuce hadayu da ciyawa da lalata abubuwa da lalata abubuwa da lalata abubuwa da lalata. Sabili da haka, barbashi a haɗe zuwa silicon foda, resin, karfe, da sauransu) kuma fada cikin tsabtatawa tsabtatawa tare da lalata lalata ruwa tare da lalacewar lalata; Saboda hadawan abu da iskar shaka na H2O2, kwayoyin halitta a saman farfajiyar da aka bazu cikin CO2, H2O kuma an cire shi. Wannan tsari na tsabtatawa ya kasance silali wa masu kera silikon ta amfani da tsaftacewa na yankan yankakken na Moncrystalline silnd werop da Taiwan da kuma sauran masana'antun batir. Hakanan akwai masana'antun batir waɗanda suka yi amfani da irin tsarin tsaftacewa na kwantar da hankali, kuma suna sarrafa bayyanar da ke faranta rai. Ana iya ganin cewa an ƙara wannan tsarin tsabtatawa a cikin silicon tsabtatawa tsari na tsabtatawa don cire matsalar farin gashi wanda ya kamata don magance matsalar farin gashi a ƙarshen baturin.

ƙarshe

A halin yanzu, yankan yankan launi na lu'u-lu'u ya zama babban fasaha na sarrafawa a fagen yankan crycon gilashin da ke samar da siliku da keɓantattun batir da keɓantattun fasahar lu'u-lu'u wafer yana da juriya. Ta hanyar kwatanta nazarin fararen farar fata, ana haifar da shi ne ta hanyar ragowar a saman wafer wafer wafer. Don fi dacewa da matsalar silicon wafer a cikin sel, wannan takarda na nuna yiwuwar gurbataccen yanayin maye na silicon, kazalika da shawarwarin inganta kuma matakan ci gaba a samarwa. Dangane da lambar, yanki da kuma siffar farin aibobi, ana iya bincika abubuwan da ake amfani da abubuwan da haɓaka. An bada shawara musamman don amfani da tsarin hydrogen peroxide + alkali tsaftacewa tsari. Kwarewar nasara ta tabbatar da cewa zai iya hana matsalar silond Wafer Waher, don yadda ake ganin masana'antun da masana'antu.

Lokaci: Mayu-30-2024